Building LCA

Home » INIES for building » Building LCA

What is a Life Cycle Assessment of a building?

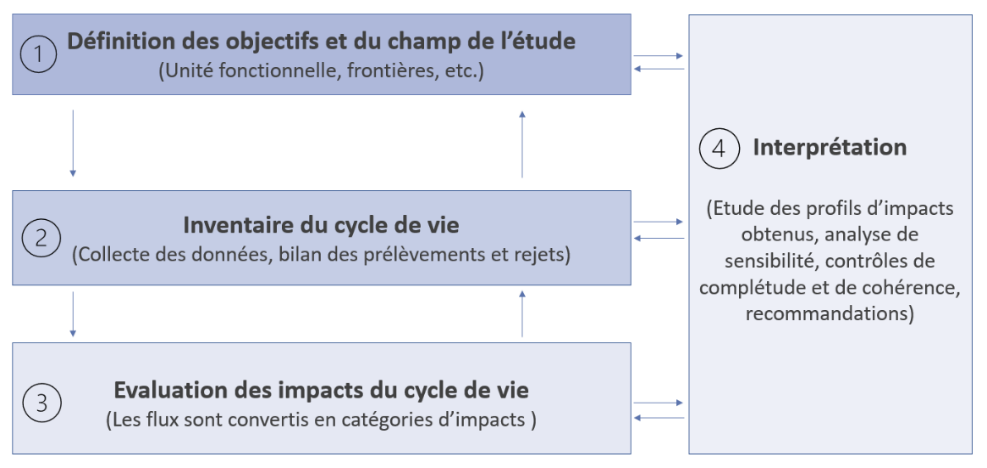

The Life Cycle Assessment (LCA) is a multi-step and multi-criteria environmental assessment method that allows quantifying the impacts of a product, service, process or construction work over its entire life cycle: from the extraction of the raw materials to its processing at the end of life. As standardised and recognised tool (international standards ISO 14040 and ISO 14044), it is the most successful method in terms of global and multi-criteria assessment.

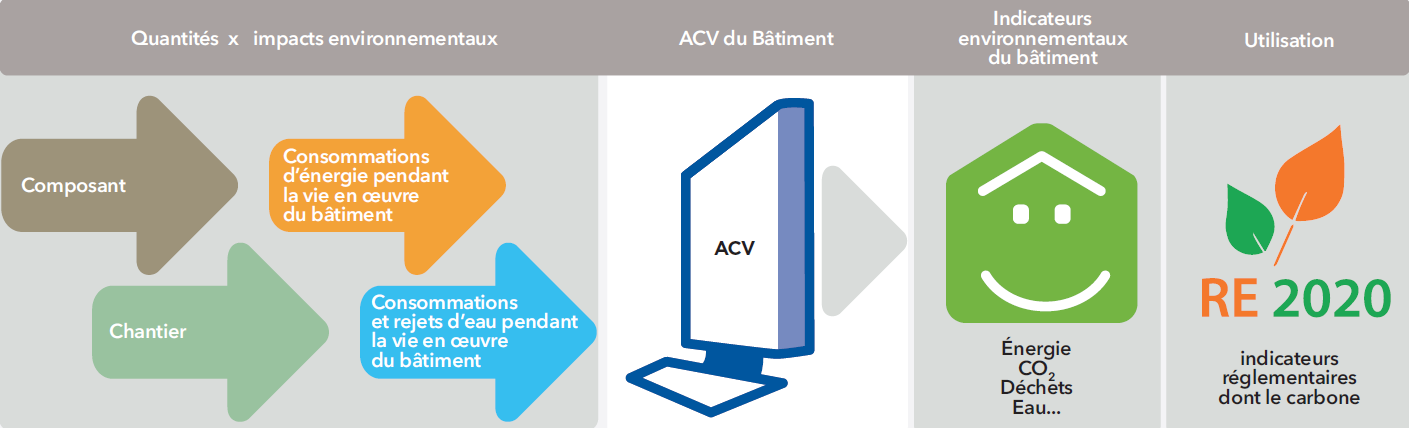

In order to understand how to specifically carry out an environmental performance assessment (LCA) of a building, the French standard NF EN 15978 details its principles and stages. The LCA of a building is made up of the sum of the LCA of the various construction products that make it up, based on the information contained in the FDES/PEP, to which are added the impacts of energy and water consumption during operation, as well as the impacts related to the construction site.

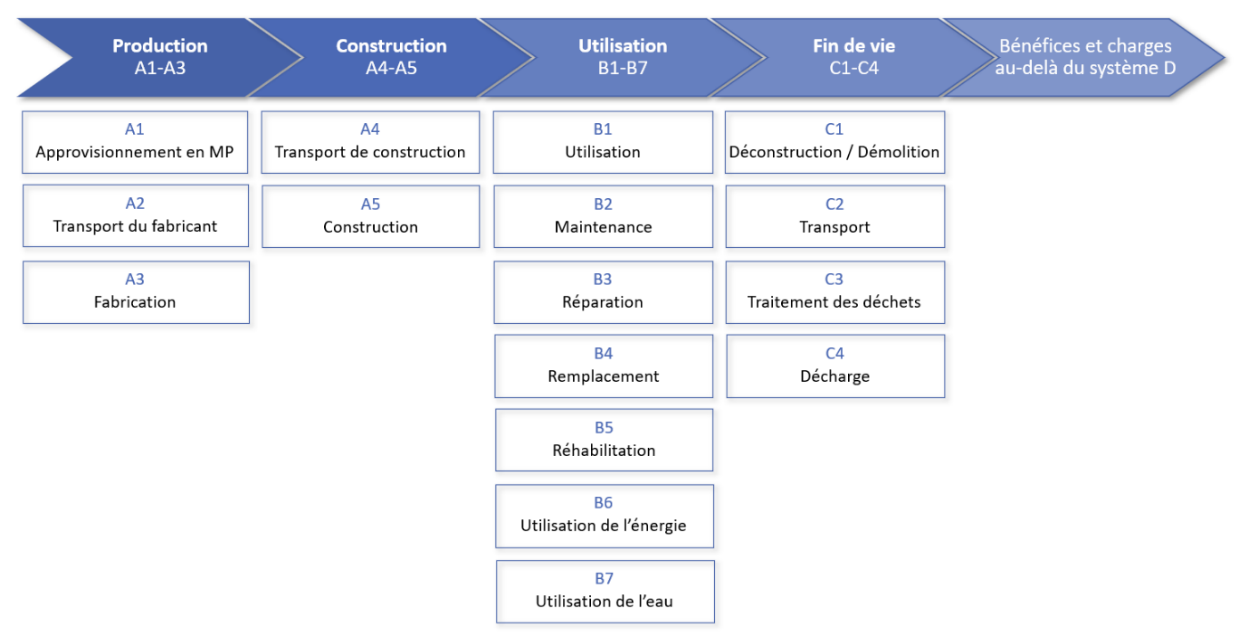

What are the life cycle stages considered?

The life cycle of a building begins with the extraction of the materials required for the production of the construction products and equipment, and ends with the deconstruction at the end of the building’s life associated with the treatment of the resulting waste, including its operation and transport between each stage.

The 5 stages:

- Production (A1-A3): Acquisition of raw materials, transport to the processing plant and production of the manufactured product

- Construction (A4-A5): Transport of the product to the site, construction process and installation of materials and finished products at the building site

- Use (B1-B7) : The entire working life of the building, including: use, maintenance, repair, replacement of materials and finished products, energy and water consumption during use of the building

- End of life (C1-C4): Deconstruction of the work, transport to the place of recovery or disposal, treatment and disposal of materials and finished products.

- Benefits and burdens beyond the life cycle (D): what can the value of the product become in a new life cycle?

Which functional unit (FU) is used?

The functional unit is the reference unit used to quantify the performance of the service rendered by a product to the user. The functional unit must include :

- Identification of the studied function(s) of the product. This (these) function(s) must describe the service provided to the user.

- The level of requirement or performance achieved by the function(s). This level must be quantified. It can be determined according to the applicable standards.

- The reference service life (RSL).

The functional unit used for the LCA of a building describes the system studied, it serves as a reference for the assessment by integrating the building(s) with its plot and its reference service life (50 years for RE2020). Products and equipment that have a shorter service life must therefore be replaced as many times as necessary until the end of the building work’s life. The use of products resulting from reuse allows reducing the various impacts of the building.

What contributions are considered in RE2020?

LCA being a global analysis, it integrates the construction (products, equipment and site) as well as the operation of a building (energy, water and renewal of products and equipment) and its end of life.

The 4 corresponding contributions are:

- Component(Construction Products and Equipment) taking into account all the elements present in the building and its plot, including the networks and parking areas of the building. They are cut into 13 batches. For each component of the building, the associated environmental declaration must be identified or if it does not exist, a DED can be used;

- Energy covering all energy consumption for heating, cooling, domestic hot water production, lighting, ventilation and auxiliaries during the building use phase;

- Water covering all water consumption of the building and its plot, the management of rainwater as well as its sanitation during its use phase;

- Building site covering energy consumption, water consumption and discharge from the site, evacuation and treatment of earthwork waste not taken into account in the “Component” contribution.

What are the 13 batches of components considered?

- Roads and various networks (VRD)

- Foundations and infrastructure

- Superstructure – Masonry

- Roofing – Waterproofing – Structural work – Zinc plating

- Bulkhead – Lining – Suspended ceilings – Interior joinery

- Exterior facades and joinery

- Floor, wall and ceiling coverings – Screed – Paints – Decoration products

- HVAC (Heating – Ventilation – Cooling – Domestic hot water)

- Sanitary facilities

- Energy networks (heavy current)

- Communication networks (low current)

- Lifts and other internal transport equipment

- Local power generation equipment

At what stages to carry out the LCA of a building?

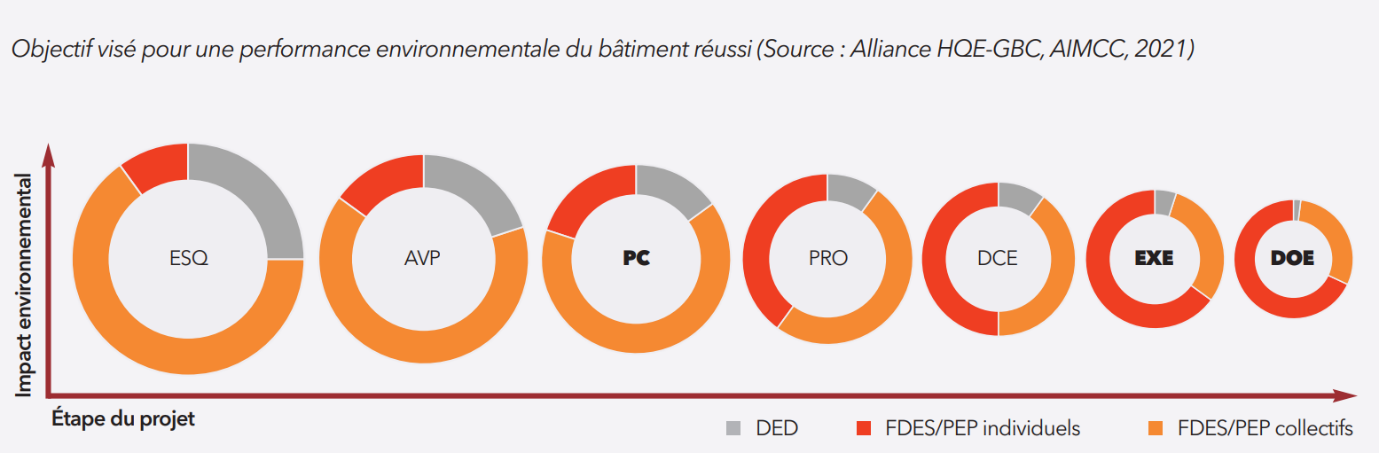

The LCA is carried out differently depending on the stage of the project. In fact, the objectives are different, the availability of data is changing and the design room for manoeuvre is decreasing.

The programming phase is a key stage for the success of eco-design. It allows to define the targeted environmental performance, to identify the issues and therefore the environmental priorities, to set the requirements for means and results, the stages of the project where the LCA will be carried out and to know what data will have to be collected (measurements, energy balances, etc.). During this phase, only a rough LCA can be carried out, using ratios and DED. In the sketch and pre-project phase, the products have not yet been chosen, measurements and quantities are difficult to obtain. The LCA is therefore subject to a large number of assumptions and uncertainties. At this stage, it allows assessing the impacts of the technical solutions considered. When applying for the building permit, the LCA will be used to ensure that the project meets the requirements of the regulations and that it reaches the set thresholds.

The design and the execution of the project are the phases where the choices of the service providers are made, the plans, sections and elevations are produced, and the nature and characteristics of the materials are defined. A detailed LCA is carried out at this stage through the use of individual ED of the CPE actually implemented. Finally, upon acceptance of the building, a DOE (Dossier des Ouvrages Exécutés / File of Executed Works) is drawn up, compiling the initial elements and the adjustments made during the construction (variation of measurements, changes of CPE, etc.). At this stage, all the data needed to carry out the LCA is available (DPGF, CCTP, DOE, plans, RSET etc.), the assessment is as detailed as possible and constitutes a picture of the construction work.

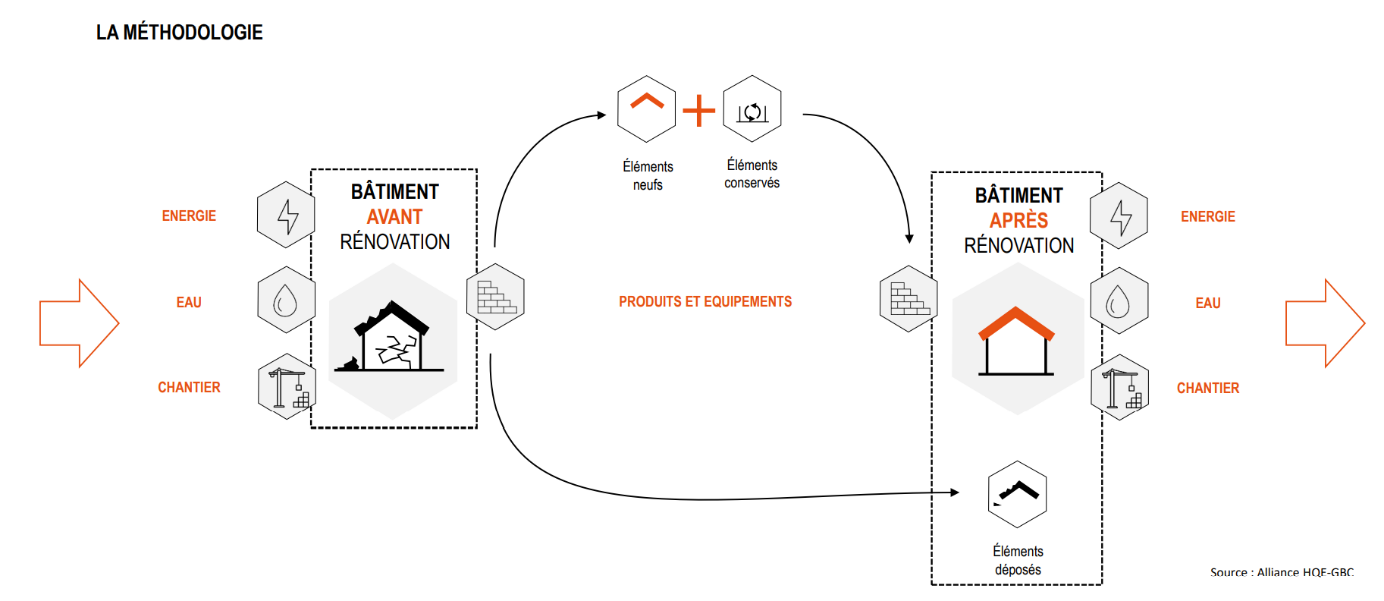

What are the specificities of a LCA of a building under renovation?

One of the LCA methods for buildings under renovation is based on an addendum to the “Carbon Energy” method for new buildings. It allows knowing whether it is better to rehabilitate, to leave as such or to deconstruct in order to rebuild. For this assessment, it is necessary to know the current water and energy consumption and those expected after the project, to carry out waste diagnostics, to estimate the CPE installed and those that will be added. The depreciation method is used for the purpose of cushioning the impacts of a CPE. These impacts are smoothed out over the lifetime of the CPE. If one or more CPE are depreciated over the LCA study period, they will therefore not be counted. The environmental impacts of new CPE and refrigerants are calculated in the same way as for a new building, i.e. 100% of the impacts.

Which tools exist to carry out the LCA of a building?

- ClimaWin edited by BBS Slama

- SustainEcho edited by SustainEcho

- OneClick LCA edited by Bionova Ltd

- Pleiades edited by IZUBA énergies

- U21Win V6 (MI) and U22Win V6 (MI and LC) edited by Logiciels PERRENOUD

- Béa edited by Bastide Bondoux

- Vizcab Eval edited by Combo Solutions

- Nooco edited by Nooco

How to choose the right data for one’s product?

In the framework of a building LCA, when choosing a product or equipment from the INIES Database, it is essential to ensure the consistency of the said product with the elements actually implemented in the building. For that, it is necessary to refer to the Functional Unit (FU) of the product or the Declared Unit (DU) for some equipment, but also to its other performances: thermal, acoustic, fire resistance, sizing, production site, etc.

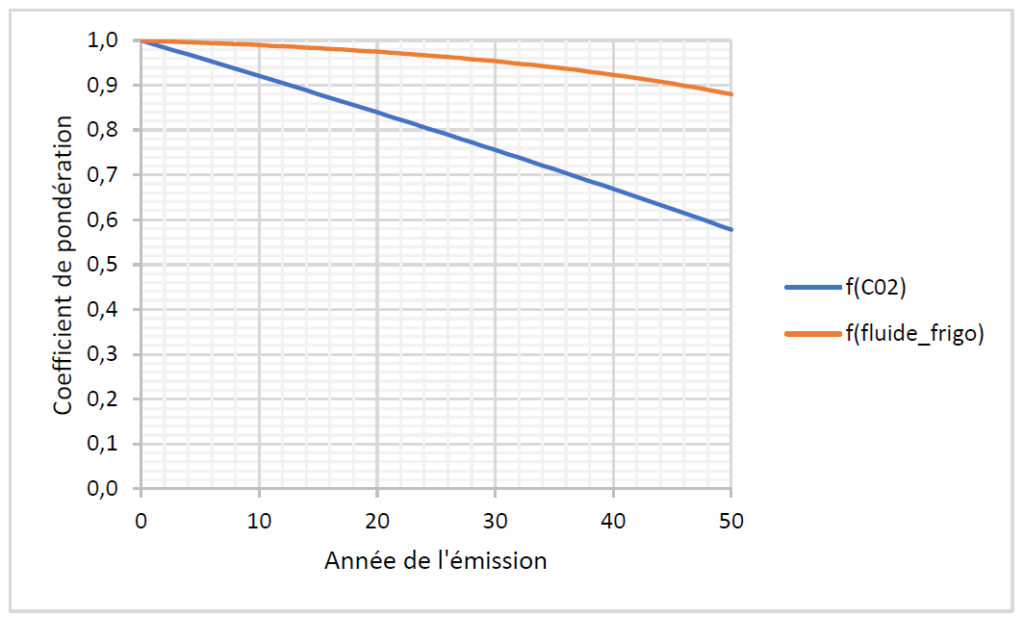

How does the dynamic LCA used for the calculation of the impact on global warming in RE2020 work?

The calculation of the impact on climate change of RE2020 is based on the dynamic approach. This approach takes into account the temporality of emissions and the effects of carbon storage. The calculated indicator corresponds to the cumulative radiative forcing 100 years after the construction of the building. The time at which the emission takes place is considered: the earlier an emission takes place, the greater will be its impact.