Product LCA

Home » INIES for building » Product LCA

What is a construction product or equipment?

A construction product or equipment (CPE) is a product intended to be incorporated into a construction work. Some products are produced in situ (on site) and others come from artisanal or industrial processes. They correspond to construction and decoration products and electrical, electronic and HVAC equipment products.

What is a specific Environmental Product Declaration (EPD)?

Products may have an environmental declaration (French FDES and PEP), also internationally called EPD (Environmental Product Declaration). This EPD is a declaration containing environmental information of the product, based on the results of a LCA, in order to calculate the environmental performance of a building. This declaration can be realized on initiative of the manufacturer, the trade union/association of manufacturers or a representative of a sector, for example a professional federation. According to the decree of December 23, 2013 and the order of July 9, 2014 on environmental labelling of construction and decoration products of the French Consumer Code, to communicate on the environmental performance of a product or equipment, manufacturers must produce a type III environmental declaration, resulting from a LCA as it is considered as an environmental claim. The manufacturers can carry out this LCA internally or call a service provider, generally a design office.

In France, for construction and decoration products, an EPD corresponds to an FDES (Fiche de Déclaration Environnementale Produit) or EHPD (Environmental and Health Declaration Sheet), and for electrical, electronic and HVAC building equipment to a PEP (Profil Environnemental Produit / Profile Environmental Product).

International standards govern drawing up of these declarations, such as the ISO 14025 standard published in 2006 which details the principles and procedures for drawing up type III environmental declarations and the ISO 21930 standard published in 2017 which specifies the main rules for drawing up environmental declarations of construction products (EPD).

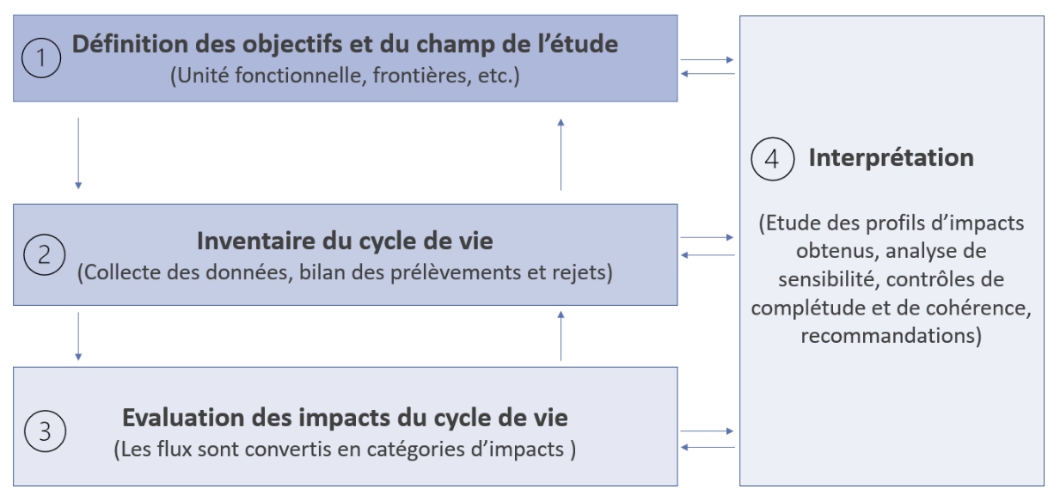

What are the 4 phases to carry out the LCA of a product?

Phase 1: Definition of the objectives and scope of the study

Firstly, the intended application of this assessment, the targeted audience and the sought level of precision are detailed. During this step the Functional Unit (FU) is defined. It corresponds to the reference and comparison unit used to quantify the performance of the service rendered by a product to the user. It includes the identification of the studied function(s) of the product, the level of performance achieved by the function(s) and the Reference Service Life (RSL). The service life allows determining the number of renewals and therefore the impacts during the building’s use phase. The boundaries of the study are then defined, they correspond to the considered stages of the life cycle, to the quality criteria of the study, to the cut-off rules used allowing elements to be neglected provided that they have negligible mass and impacts.

Phase 2: Life Cycle Inventory

It corresponds to the balance of all incoming and outgoing flows of the studied system. The service provider, who carries out the LCA, supports the manufacturer in collecting the data, and then quantifies them in the appropriate units. These data are specific for the production and correspond to generic scenarios for the use and end-of-life phases. These data are then brought back to the reference flow, allowing matching the FU.

Phase 3: Life cycle impact assessment

It allows getting from about one hundred flows to the 28 environmental indicators of EN 15804+A1 standard. These indicators allow measuring the environmental impacts caused by the product, thanks to a characterisation of emission flows and of resource consumption. This step is done automatically by the product LCA software.

Phase 4: Interpretation

Finally, the results obtained are interpreted in order to draw conclusions from the study or to improve part of this study. The analysis of the impact profiles is carried out, as well as a sensitivity assessment, a control of the completeness and coherence of the study. The LCA specialist then accompanies his client to suggest which environmental actions to prioritise.

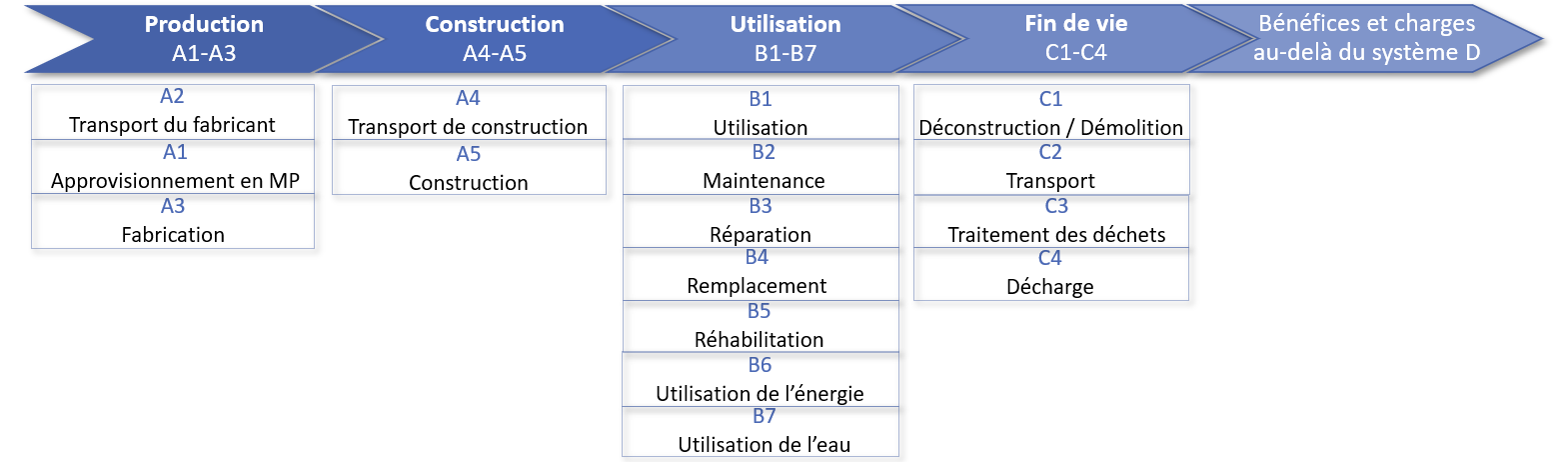

What stages of the product life cycle are taken into account?

The NF EN 15804+A1 2014 standard details the four main stages of the product or equipment life cycle. These stages correspond to the production of materials, the construction, the use and the end of life of the building, namely from “cradle to grave”. Each of the main steps is divided into sub-steps.

What environmental indicators are assessed?

The global warming indicator

To know the impact on climate change called “carbon” impact of a product, use the global warming potential (GWP). It counts gas emissions contributing to the greenhouse effect throughout the product’s life cycle. Its unit is the CO2 equivalent kg, which means that it includes all emitting gases: carbon dioxide (CO2), methane (CH4), chlorofluorocarbons (CFC), nitrous oxide (N2O), etc.

All these values (products and equipment) are necessary for the carbon calculation at the building scale for E+C- and RE2020. Energy indicators

The nine LCA indicators directly related to energy consumption and recovery are described below and are expressed in megajoules (MJ), knowing that one megajoule is equal to 0.278kWh. These indicators do not only calculate the consumption during the use phase of the product or building, but also quantify the energy required for production, transport and end of life.

The use of renewable primary energy (wind, solar, geothermal, hydrothermal, hydroelectric, biomass, landfill gas, sewage treatment plants gas and biogas, etc.) or non-renewable (oil, coal, gas, nuclear, etc.) are indicators that express the amount of energy that is consumed at the different stages of the product’s life cycle in order to operate systems, equipment and processes.

Then, the use of renewable (wood, etc.) or non-renewable (plastics, etc.) primary energy resources as raw materials, corresponds to the quantity of primary energy contained in the raw materials consumed to manufacture a product.

The total amount of renewable energy consumed is calculated, as well as the total amount of non-renewable energy. - Use of renewable primary energy excluding renewable primary energy resources used as raw materials

- Use of renewable primary energy resources used as raw materials

- Use of non-renewable primary energy excluding non-renewable primary energy resources used as raw materials

- Use of non-renewable primary energy resources used as raw materials

Indicators related to the circular economy

The eleven LCA indicators directly related to the extraction or reuse of materials, their use and their end of life are described below. The depletion of abiotic resources expresses the quantity of “rare” materials (metals, etc.) or energy (gas, oil, coal, etc.) consumed at the different stages of the product’s life cycle. Its unit is expressed in antimony (Sb) equivalent. Antimony is a resource considered as finite on a human scale, and has a value of 1 by convention. A value greater than 1 for a resource indicates that a rarer resource than antimony is being consumed (eg: 1kg gold = 52kg eqSb, 1kg iron = 0.0000000524kg eqSb).

Then, the use of secondary materials corresponds to the quantity of materials recovered after a first use or resulting from waste which replaces virgin materials, and which are integrated into the product. The use of renewable (wood from deconstruction, green waste, etc.) or non-renewable (plastic waste, etc.) secondary fuels corresponds to the quantity of energy consumed from fuels recovered after a first use or from waste, which replaces primary fuels.

Then, the indicators related to production and processing of eliminated hazardous, non-hazardous or radioactive waste correspond to the quantity of waste produced which is buried or incinerated. Finally, the mass of components intended for reuse, recycling or energy recovery is estimated.

Finally, the electrical, steam or gas energy supplied to the outside corresponds to the quantity of energy produced by energy recovery during the manufacturing phase of the product or waste recovery (household waste incineration plants).

Learn more about the circular economy - Depletion of abiotic resources – minerals and metals (kg Sb eq)

- Depletion of abiotic resources – fossil fuels (MJ)

- Use of secondary material (kg)

- Hazardous waste (kg)

- Non-hazardous waste (kg)

- Radioactive waste disposed (kg)

- Components for reuse (kg)

- Materials for recycling (kg)

- Materials for energy recovery (kg)

- Use of renewable secondary fuels (MJ)

- Use of non-renewable secondary fuels (MJ)

- Energy supplied externally in MJ per energy carrier *

- Energy supplied externally electricity in MJ

- Energy supplied externally steam in MJ

- Energy supplied externally heat in MJ

Indicators related to biodiversity

There are no indicators directly linked to biodiversity, but six indicators allow carrying out an indirect assessment of this impact. Indeed, soil, air and water pollution and acidification are factors of biodiversity loss. Thus, the lower the values of these indicators, the less the project impacts biodiversity.

The indicator related to global warming expresses the additional greenhouse effect potential generated by GHG emissions (CO2, CH4, CFC, N2O, etc.) at the different stages of the life cycle of a product or project.

Then, the indicator linked to the depletion of the ozone layer quantifies the emissions of CFC (ChloroFluoroCarbon) or HCFC (hydroCFC). These emissions react with the ozone molecules present in the stratosphere and therefore limit filtering of ultraviolet rays.

The indicator linked to soil and water acidification quantifies the emissions of compounds likely to be transformed into acids (SO2, NOx, NH3, HCl, etc.) leached by precipitation and ending up in water or soil.

Eutrophication expresses the potential of water enrichment in nutrients generated by emissions at the different stages of the product’s life cycle. This excess of nutrients decreases biological diversity and water quality.

Then, the indicator linked to the formation of photochemical ozone quantifies the emissions of VOC leading to the formation of tropospheric ozone. Ozone, although protective in the upper layers of the atmosphere, is a dangerous and irritating gas for the respiratory tract.

Finally, the indicator linked to the net use of fresh water corresponds to the quantity of fresh water consumed at the different stages of the life cycle of the product or project. - Ozone depletion in CFC-11 eq

- Soil and water acidification inkg SO2 eq

- Eutrophication in kg (PO4)3-

- Photochemical ozone formation in kg C2H4 eqAir

- Pollution in m3

- Water pollution in m3Net freshwater use in m3

Why carry out the LCA of a product?

The LCA of a product is the first step of its eco-design, it allows a complete and multi-criteria diagnosis, throughout its life cycle. The industrial can then identify the possible actions to reduce the most significant impacts of his product. These declarations are collected in the INIES database with a view to assess the environmental performance of buildings.Is the verification of environmental declarations mandatory?

With the order of 31 August 2015, the verification of declarations, by an independent third party, in accordance with the ISO 14025 standard, is mandatory since 1 July 2017. This verification is carried out by an expert; this person must be accredited for the PEP verification programme to verify PEP and to the INIES verification programme to verify FDES. The verifier analyses the conformity of the study with regard to good practices and carries out a critical review including a study of the assumptions made, the plausibility of the results and the objectivity of the conclusions. He can ask for modifications of the study or for justifications. A verification certificate signed by the verifier is issued and accompanies the study. These declarations are valid for 5 years and shall be updated during this period of validity if one of the indicators varies by more than 10%.

What are the two types of environmental declarations?

Individual declaration

Individual FDES and PEP are made by a single manufacturer for a specific product or product line. This allows knowing the real impacts of the product and to promote it to specifiers.

Collective declaration

A collective declaration is made for the same typical product manufactured by several industrials. To fall within the case of a collective declaration, it is necessary to respect a validity framework which specifies the rules and requirements appying to collective environmental declarations. It defines the methodology for carrying out the latter, the conditions relating to the communication of environmental impacts according to the dispersion of the results and the rules and conditions binding the manufacturers (validity interval to be respected). This framework is available in the declaration.

Collective declarations are useful for drawing up building LCA, especially for the design phase, when the exact brands of the products are not known.